Colloid Mill

Ointment

Colloid Mill

Colloid Mill horizontal model

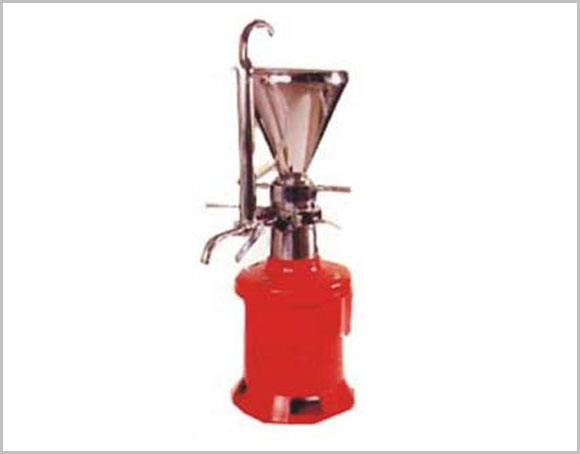

Colloid Mill vertical model

Vitro Pharma Machine provides Colloid Mill-horizontal model which is suitable for homogenizing, emulsifying, dispersing, mixing, comminuting of liquids to highly viscous products. The product Colloid Mill horizontal model is based on rotor and stator principle. This unique design provides smooth and consistent all-around performance and long life of rotor and stator.

- Excellent for the homogeneous blending of different liquids having different viscosity.

- Three-way cock for draining and re-circulation of fluids provided as standard.

- Contact parts can be easily dismantled for cleaning.

- Special design facilitates adjustment of the fine grinding gap by an exterior screw by means of handle even during operation.

- Colloid Mill horizontal model is available in plain as well as a water jacketed model which is suitable for the heat-sensitive product.

Vitro Pharma Machine provides Colloid Mill vertical model is used to reduce the particle size of a solid in suspension in a liquid or to reduce the droplet size of a fluid suspended in another liquid. Also, Colloid Mill is used for various applications such as Superfine grinding, homogenizing, emulsifying, dispersing, mixing and extracting of liquids, ointments and highly viscous products in pharmaceutical, cosmetics, suspensions & emulsion industry.

| Technical Specifications | ||

| Model | Vertical Model | Horizontal Model |

| Output | 120 / 12000 Kgs per shift | 120 / 12000 Kgs per shift |

| Particle size reduction | 5 - 10 microns [depending on material] | 5 - 10 microns [depending on material] |

| Hopper capacity | 15 litres | 15 litres |

| Motor | 3 HP, 2850 rpm, 440 V, 50 Hz, 3 Phase | 3 HP, 2850 rpm, 440 V, 50 Hz, 3 Phase |

| Height | 1200 MM | 1170 MM |

| Floor space | 410 X 680 MM | 390 X 990 MM |

| Case dimensions (mm) | 550(w) x 830 (d) x 1300 (h) | 530 (w) 1130 x (d) x 1270 (h) |